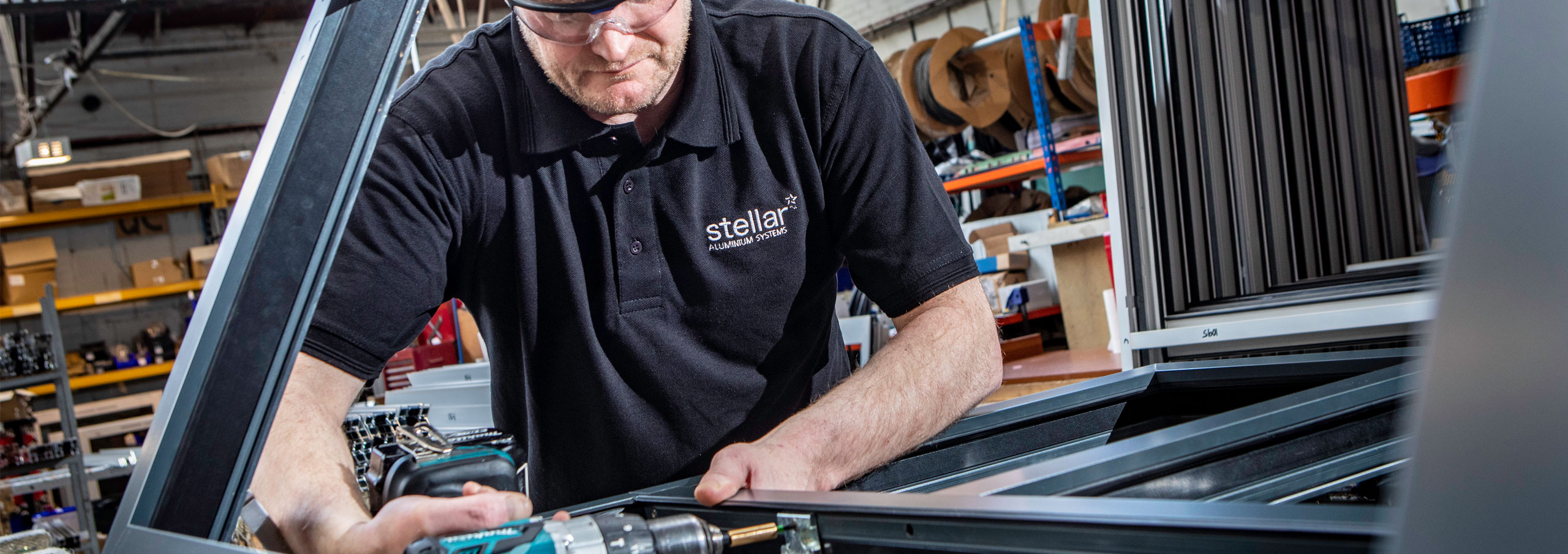

Manufacturing is simpler – across the board – with patented innovations that slash the fabrication time, reduce waste and save materials. Multilight windows become easy, and frames retain their clean lines. Forget shootbolts on casement windows, Stellar is built for fast-fit espags. Reduce the hassle of corner ties – you won’t need as many. What’s more, your stock levels will be easier to manage because many parts are consistent across the suite.

Stellar is adaptable too. If you want to use mechanical jointing, go ahead. If you want to use cost-effective PVC-U cills, you’ll find them a perfect fit. If you want to achieve a certain level of performance, you’ll find all the specifications are covered in Stellar’s U-Comply N data.

If you strive for manufacturing excellence, you’ll find it easy to reach with Stellar.

Save materials:

- Pre-gasketed system reduces waste

- Innovative Reverse Butt Joint – no dummy sashes or reverse adaptor profiles needed – saves up to 30% on profile*

* Based on a GGF standard configuration internally beaded window.

Reduce stockholding

- Consistency in design of profiles, hardware and accessories

- Compatible with PVC-U cills

Save fabrication time:

- Pre-gasketed system saves up to 20% on fabrication time

- Patented knock in bead systems for faster, easier glazing

- Chevrons or corner ties are only required on the flush sash

- Takes fast-fit espagnolettes – no shootbolts required

- Direct fix hardware

More benefits:

- Enhanced PAS24 security

- Reverse Butt Joint gives around 12% more glazed area

- Cost-effective solution

- U-values easy to calculate

- Sashes can be crimped or mechanically jointed for flexibility in manufacturing.